What is waste-to-energy?

Currently, there are three primary methods for disposing of household waste: sanitary landfilling, composting, and incineration for power generation. However, landfilling requires a significant amount of land and can easily lead to secondary pollution. Composting is slow and only suitable for small-scale applications. As a result, incineration for power generation has become the mainstream waste disposal method due to its minimal land consumption, fast processing speed, reduced secondary pollution, and potential for resource reuse.

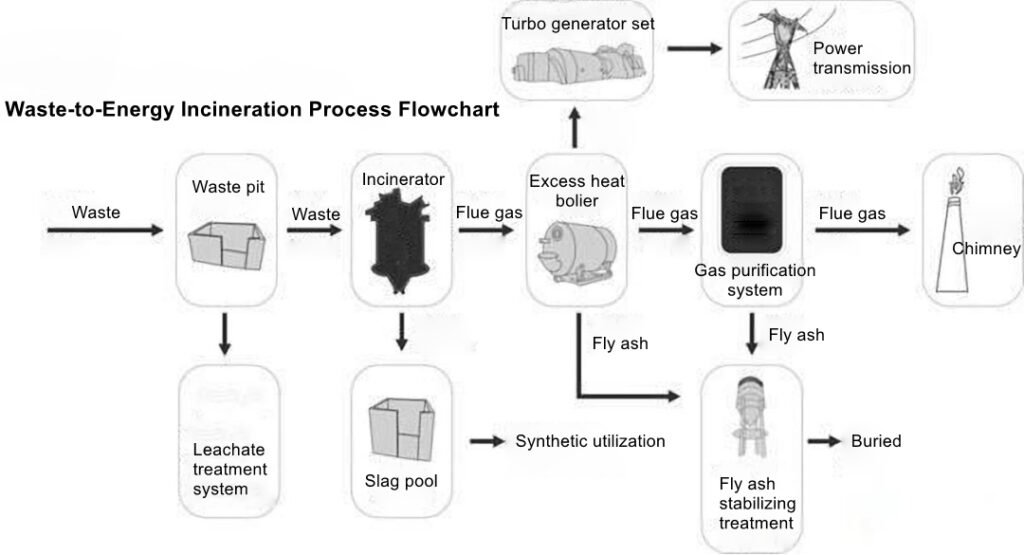

The main process of waste-to-energy:

As shown in the above diagram, household waste is unloaded into the waste pit by sealed transport vehicles. The waste pit is an enclosed structure that maintains negative air pressure during normal operation to prevent odor escape.

After being left to stand in the waste pit for 2 to 5 days to drain off moisture, the household waste is fed into the incinerator feed hopper by a grab crane. It then enters the grate for combustion via the chute. The heat generated by the incineration of waste will be used to generate electricity for the turbo generator set.

How to dispose of pollutants generated by incineration power generation?

During the incineration of household waste, the main harmful gases that may be produced include dioxins, incineration flue gas, and odors. To address this, the waste incinerator will strictly control the incinerator temperature to above 850°C to effectively limit dioxin production. The flue gas generated after waste incineration will enter the built-in flue gas purification system, which effectively controls pollutant production and ensures emissions meet standards. Deodorizing air ducts and activated carbon purification devices installed above the waste pit will effectively reduce the impact of odors.

The primary noise sources during the waste incineration process include equipment such as air compressors, fans, water pumps, and cooling towers. To mitigate noise, low-noise models will be selected. Noise and vibration reduction measures, such as installing soundproof covers and vibration-damping pads, will be applied to high-noise and high-vibration equipment. Additionally, noise absorption will be achieved through measures such as using enclosed workshops, installing soundproof doors and windows, strategically arranging plant layout, and optimizing the landscaping of the plant area.

Wastewater treatment follows the principle of “separating rainwater from sewage and clean water from dirty water.” The concentrate produced during the treatment process is reduced in volume and then sprayed back into the waste incinerator, achieving zero wastewater discharge.

The slag produced by waste incineration undergoes high-temperature treatment to render it harmless and is then separated using magnetic separation and other methods. This processed slag can be comprehensively utilized, for example, by being made into environmentally friendly bricks and other building materials. The portion that cannot be utilized is sent to sanitary landfills for disposal.

What benefits does waste-to-energy incineration bring to us?

- It helps conserve land resources. After waste is incinerated, the resulting slag constitutes only 15-20% of the original volume and can be completely recycled. The fly ash produced amounts to just 2-3% and only requires deep burial. This process can save over 80% of land resources.

- It enhances environmental benefits. High-temperature incineration of household waste thoroughly eliminates a large number of viruses, bacteria and other pathogens, effectively preventing secondary pollution. By employing advanced incineration and pollution control technologies, zero discharge of leachate and production wastewater can be achieved, flue gas emissions can meet standards, and fly ash can be treated stably. This effectively addresses significant environmental issues such as the breeding of mosquitoes and flies, air odors and leachate leakage.

- It supports resource utilization. Waste-to-energy incineration technology allows for the generation of approximately 300 to 500 kWh of electricity per ton of waste, providing substantial economic benefits. Additionally, it replaces coal-fired power generation, leading to significant reductions in carbon emissions.