The main safety accessories on a steam boiler are the pressure gauge, safety valve, and water level gauge. These devices are essential for monitoring and controlling the water level, ensuring the boiler’s safe operation. This is why they are called the three key safety accessories.

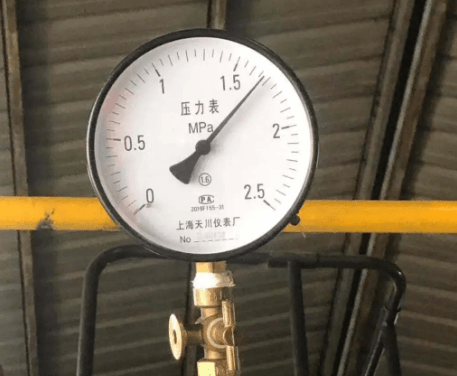

Pressure Gauge

The pressure gauge measures the boiler’s internal pressure during operation. It helps operators manage the boiler safely and correctly.

Each boiler must have a pressure gauge directly connected to the steam space of the drum. The gauge’s accuracy depends on the boiler’s working pressure. It should be selected accordingly. The installation should allow easy observation and cleaning. It should also be protected from radiant heat and vibrations. There should be a three-way valve and a water trap below the gauge. Installation, inspection, and maintenance must follow national standards. The gauge should be calibrated at least every six months, and a lead seal applied after calibration.

Safety Valve

The safety valve automatically stops the boiler’s steam pressure from exceeding the allowed range, ensuring safe operation.

When the boiler’s pressure reaches its limit, the safety valve opens automatically. It releases steam and triggers an alarm to warn the operator. The valve stays open until enough steam is released to lower the pressure below the limit. Then, the valve closes automatically. This keeps the pressure within safe limits and prevents explosions.

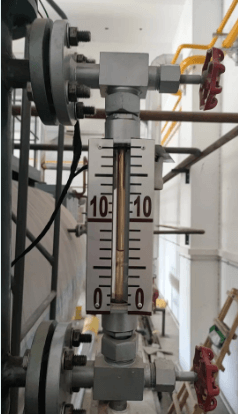

Water Level Gauge

The water level gauge is a vital safety device. It monitors the water level inside the boiler drum. The gauge shows the actual water level in the boiler. The operator uses this information to ensure the boiler operates safely.

Users should note:

- Install the correct number of water level gauges according to design specifications;

- Place them in easy-to-see locations;

- Mark the gauge with clear indicators for maximum, minimum, and normal safe water levels;

- Keep connecting pipes short and horizontal to avoid false readings.

About Us

Shandong Bokk Tech is dedicated to solve the problem such as ash blockage, corrosion and excessive exhaust gas temperature in the tubular air preheater of small and medium-sized boilers. We primarily manufacture automatic cleaning devices for tubular air preheaters and corrosion-resistant heat pipes. Our products are widely used in the thermal power plants, chemical plants, new energy sector, etc.

We offer customized services to customers around the world, allowing us to adjust product dimensions and other specifications based on your specific needs, to improve air preheater heat efficiency.

Share The Post