Rare earth alloy composite pipes and stainless steel composite pipes are the common types of heat pipes used in air preheaters. Each has unique advantages suited to different situations. Comparing them helps us understand their performance and best uses.

In terms of material composition

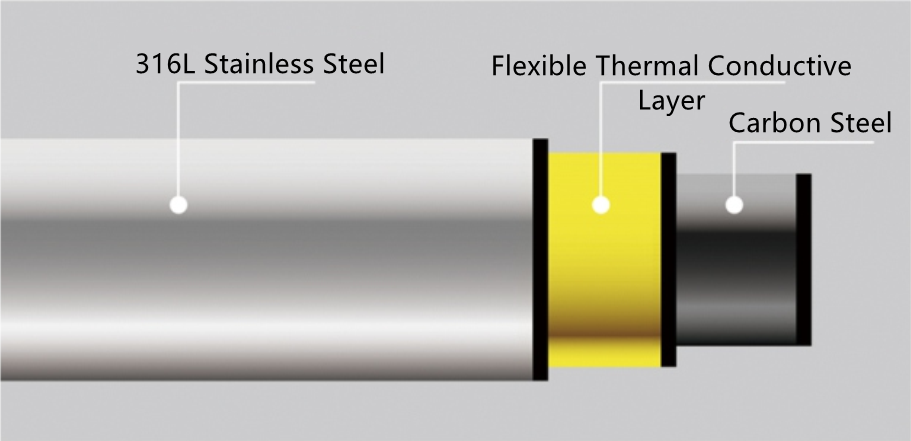

Rare earth alloy composite pipes combine rare earth elements with alloy materials. They offer excellent corrosion resistance and perform well at high temperatures. Stainless steel composite pipes, however, are made by combining stainless steel with other metals or non-metals. These pipes provide strong resistance to corrosion and excellent strength. The differences in materials lead to different performance characteristics.

In terms of applications

Rare earth alloy composite pipes perform well in high-temperature and highly corrosive environments. They are often used where high temperatures, high pressure, and strong corrosion are present. Stainless steel composite pipes, in contrast, are strong and corrosion-resistant, making them suitable for a wide range of challenging conditions.

In terms of production processes

Rare earth alloy composite pipes require a complex process with precise alloy ratios and high-temperature smelting. This ensures stable performance. Stainless steel composite pipes, however, are easier to produce. They are typically made using welding or mechanical bonding to combine different materials.

In terms of cost

Rare earth alloy composite pipes are cheaper to produce, but their manufacturing process is more complex. Stainless steel composite pipes, however, are more expensive to produce but involve a simpler production process.

In summary

Rare earth alloy composite pipes and stainless steel composite pipes have distinct advantages. The choice should depend on the specific application. In practice, consider factors like installation, maintenance, and service life. Rare earth alloy composite pipes may have higher installation and maintenance costs due to their special materials and production process. However, their long lifespan and excellent performance can lower long-term costs. Stainless steel composite pipes, on the other hand, are less costly to install and maintain. But they may need more frequent upkeep in harsh environments.

In conclusion, these two types of pipes have different benefits. The choice should be based on specific needs and scenarios. It’s also important to consider performance, cost, installation, and maintenance. Bokk Tech manufactures both types of composite pipes to meet your different needs. With ongoing technological advances, the potential uses for both materials will continue to grow.

About Us

Shandong Bokk Tech is dedicated to solve the problem such as ash blockage, corrosion and excessive exhaust gas temperature in the tubular air preheater of small and medium-sized boilers. We primarily manufacture automatic cleaning devices for tubular air preheaters and corrosion-resistant heat pipes. Our products are widely used in the thermal power plants, chemical plants, new energy sector, etc.

We offer customized services to customers around the world, allowing us to adjust product dimensions and other specifications based on your specific needs, to improve air preheater heat efficiency.

Share The Post