Common materials for air preheater heat exchange pipe currently include Q235, Corten steel, ND steel, enamel pipes, etc. These materials are continually being upgraded, each offering its own set of merits and demerits:

- Q235 Material

Initially, most air preheaters were made of this material. While it is inexpensive, it has low corrosion resistance.

- Corten Steel Material

This material is plain carbon steel alloyed with small amounts of copper, nickel, and other corrosion-resistant elements. It is resistant to dew point corrosion, but it does not withstand chloride and ammonia corrosion at high temperatures.

- Enamel Pipe Material

Enamel is coated on plain carbon steel. The advantage is its resistance to flue gas corrosion. However, it is prone to concentrated point corrosion due to enamel chipping during installation, transportation, and maintenance. The end welding can cause micro-cracks, leading to failure in corrosion protection. Additionally, wet enamel can form pores from the evaporation of organic solvents, causing point corrosion.

- Fluoroplastic Steel Material

This composite material involves directly molding soluble PFA or other fluoroplastics onto the surface of metal pipes through hot melt, creating a seamless and tight bond with the metal pipes. The advantages include strong wear resistance and rigidity; however, it suffers from poor thermal conductivity and accumulated ash is difficult to clean.

BOKK TECH has upgraded and launched rare earth alloy composite materials and stainless steel composite materials as the air preheater heat exchange pipes with stronger corrosion resistance based on the previous.

1. Rare Earth Alloy Composite Pipe Material

The surface of carbon steel is coated with rare earth alloy, which has strong adhesion and bonding strength. Additionally, a corrosion-resistant sealing agent is applied, providing double-layer protection and stronger corrosion resistance.

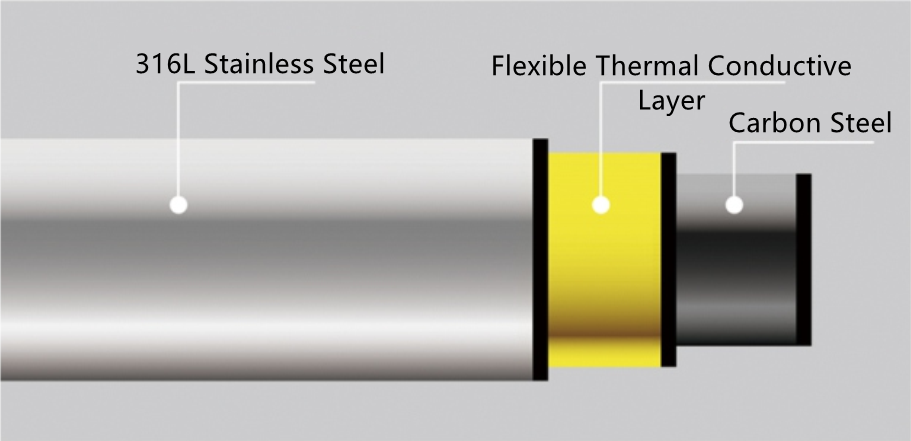

2. Stainless Steel Composite Pipe Material

316L stainless steel is alloyed with 2-3% Mo, which offers excellent resistance to pitting corrosion.

3. Saw-vibration Automatic Ash Cleaning Device

Aluminum alloy is used for the serrated stripe, allowing for more effective ash removal without damaging the pipes

Share The Post