Elliptical tube air preheater has a significant improvement in efficiency compared to traditional circular tube. The original circular tube air preheater suffers from high wind resistance and low efficiency. In comparison, elliptical tubes offer better aerodynamic properties, lower flow resistance, and longer time for dust to accumulate between them. With equal cross-sectional areas, elliptical tubes have a longer heat transfer perimeter, enhancing heat transfer and allowing for a more compact structure.

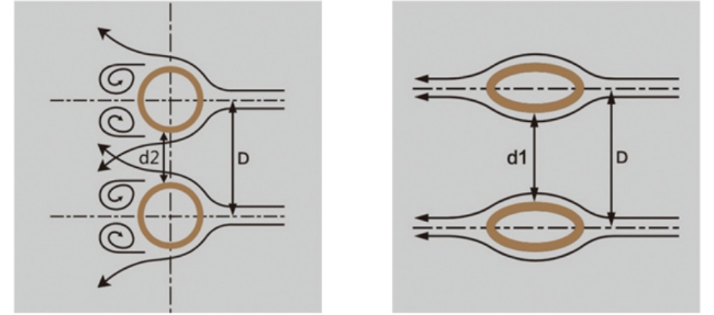

With the same windward area, the net flow area between the tubes of an elliptical tube air preheater is 17% to 22% larger than that of the circular one. Experiments conducted under turbulent conditions on staggered circular and elliptical tubes revealed that the heat transfer coefficient of elliptical tubes is 15% higher, while their resistance is 18% lower compared to circular tubes.

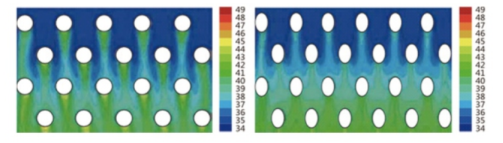

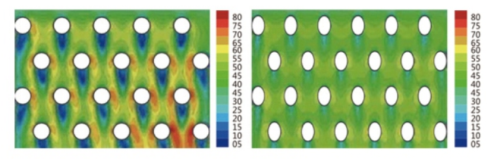

For a specific heat exchange amount, the elliptical tube air preheater requires a smaller heat exchange area and consumes less power compared to the circular one. In an air preheater with the same air volume and windward area, the actual net flow channel air face velocity of the elliptical tube is reduced by 15% to 18%, while its effective contact surface area is increased by 40%. CFD (Computational Fluid Dynamics) simulations of the velocity and temperature distribution reveal that the elliptical tube has a more uniform distribution of both velocity and temperature around it, promoting more efficient heat exchange.

In conclusion, elliptical tubes have several clear advantages over circular tubes

- Improved Heat Transfer Performance

For the same perimeter, an elliptical tube has a smaller cross-sectional flow area than a circular tube. If the flow rate remains constant, this enhances the disturbance, thereby strengthening the convective heat transfer inside the tube. Externally, considering the fluid separation point position and boundary layer development, the average heat transfer performance around the elliptical tube is consistently better than that of the circular tube. The streamlined shape of the elliptical tube results in lower fluid flow resistance, allowing for higher flow speeds under the same allowable flow resistance, which enhances external heat transfer as well.

- Superior External Flow Characteristics:

When fluid flows transversely along the long axis of the elliptical tube, the separation point moves backward, significantly reducing flow losses caused by the Kármán vortex street in the separation zone.

- Compact Structure

With the same flow area, the elliptical tube’s longer heat transfer perimeter increases the heat exchange area. This structural feature allows for a more compact arrangement, thereby increasing the heat exchange capacity per unit volume.

Share The Post