Sonic ash cleaning refers to the use of the energy of the sound field to remove ash from the surface of the boiler heat exchanger.

It generates sound energy by oscillating pressure within a cavity, emitting high-intensity sound waves. This causes air molecules and dust particles in the affected areas to resonate, preventing and disrupting the bonding of dust particles on heat exchanger surfaces or between particles, thereby achieving effective ash removal.

There are also a series of issues that need attention during ash removal:

- Limited ash removal effectiveness

The sonic ash cleaning devices may not be ideal for sticky or heavily scaled ash deposits.

- Requirements for equipment structure

Installing and using sonic ash cleaners require certain modifications and adaptations to the equipment structure, which increases complexity and cost.

- Noise problem

Sonic ash cleaning devices generate noise during operation. It requires appropriate noise reduction measures to minimize the impact on operators and the surrounding environment.

- Limited energy and effective range

The energy of sonic ash cleaners is relatively low, and their effective range is limited.

- High equipment investment

Sonic ash cleaning devices require an air compressor station, resulting in a significant initial investment in equipment.

- Requirement of regular drainage and lubrication

The filter requires regular drainage to prevent freezing and rupture. Additionally, the oil mist generator of the sonic ash cleaner needs periodic refueling to ensure proper operation.

- Susceptible to ash accumulation

Ash accumulation in the air source system, body, and horn can impede sound wave propagation and reduce ash cleaning effectiveness, requiring timely cleaning.

- Installation constraints

Installing sonic ash cleaning devices with amplification structures may be restricted in high-temperature areas. Furthermore, due to their limited effective range, more sonic ash cleaners may be needed compared to the traditional.

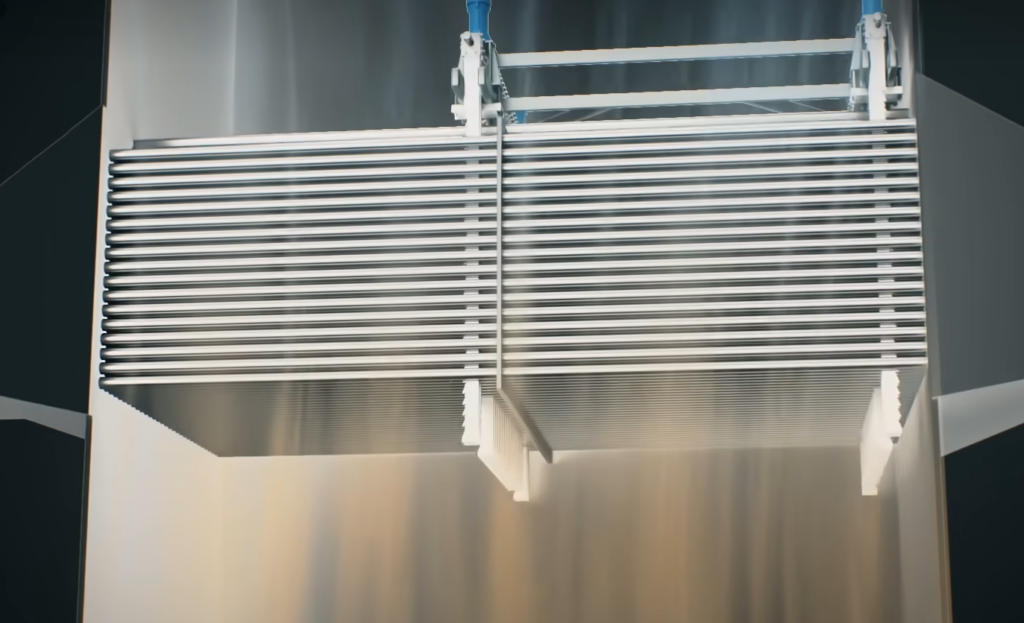

The saw-vibration ash cleaning device addresses these problems by enabling timely contact cleaning without the need to shut down the boiler.

Its advantages include:

- Realize automatic operation without stopping the furnace.

- Use lightweight, low-hardness serrated strips that prevent damage to the pipes

- Effectively resolve the issue of ash accumulation at both ends of the pipes, which sonic ash cleaner cannot clean

- Use PLC automatic control and remote access to the DCS control system

- Products of different specifications can be customized according to the specifications of the air preheater and operating conditions.

Share The Post