Mechanical online ash cleaning is an efficient and intelligent way to remove the ash accumulation, which can automatically clean the air preheater without stopping the boiler. It greatly improves the operating efficiency and safety of the boiler. The following is a detailed introduction to the mechanical online ash-cleaning:

1. PRINCIPLE

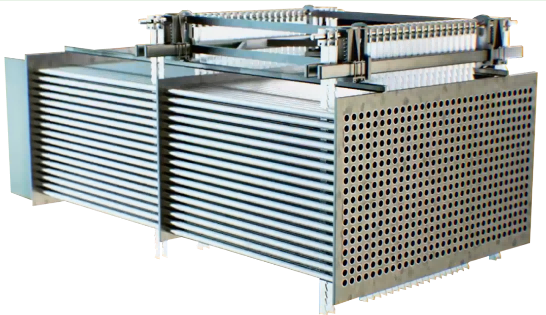

It primarily involves the installation of specific mechanical devices, such as saw-vibration cleaning systems, on the air preheater to remove accumulated ash. These devices use mechanical force to directly act on the accumulated ash, carrying out operations such as impacting, vibrating, scraping, and sawing to effectively remove ash from the surface of the air preheater.

2. ADVANTAGE

- Efficiency: It directly targets the accumulated ash, providing significant cleaning effectiveness. It is not limited by factors such as ash stickiness or spatial location.

- Intelligence: It is equipped with remote automatic control function, which can adjust the cleaning time and frequency based on real-time conditions to achieve intelligent management.

- Non-stop cleaning: Ash cleaning can be carried out during boiler operation without requiring a shutdown, thereby improving the boiler’s utilization rate.

- Risk reduction: It reduces the safety risks associated with manual cleaning and also the economic losses caused by shutdown cleaning

3. METHOD

At present, mechanical online dust cleaning devices have developed several generations of products, among which the more advanced one is the saw-vibration dust cleaning device. This device uses the sawtooth cleaning blades to move vertically up and down while reciprocating back and forth. The vibration and sawing action of the saw-teeth provide comprehensive cleaning of the air preheater. The saw-vibration cleaning device effectively overcomes the shortcomings of traditional ash cleaning methods, such as the comb-tooth cleaning device, which tends to accumulate dust at both ends, shortening the cleaning stroke, and the rope-slide cleaning device, which can potentially wear down the heat exchange pipes.

4. APPLICATION EXAMPLE

In practical applications, mechanical online ash cleaning devices have been widely used in various types of boilers, especially those biomass boilers with high dust viscosity and easy hardening. By installing mechanical online ash cleaning equipment such as saw-vibration dust cleaning devices, the operating efficiency of these boilers has been significantly improved, while also reducing the number of shutdowns and maintenance costs caused by dust blockage.

5. CAUTIONS

When performing mechanical online dust cleaning, the following points should be noted:

- Ensure the installation quality and operating stability of the device to avoid damage to the air preheater.

- Adjust the cleaning time and frequency according to actual conditions to achieve the best effect.

- Regularly inspect and maintain the cleaning device to ensure its normal operation.

- Pay attention to safety precautions during the cleaning process to avoid accidents.