There are three main types of air preheaters: plate, tube and rotary.

Air preheater, referred to as air preheater, is an important auxiliary equipment in the boiler system. It is mainly used to increase the temperature of the air entering the boiler, thereby improving combustion efficiency and reducing energy consumption. According to its heat transfer mode and structural characteristics, air preheaters can be divided into three types: plate, tube and rotary. The specific introduction is as follows:

Plate air preheater

Advantages: Plate air preheater is usually made of thin steel plates with a thickness of 1.5-4 mm, with a large heat exchange area and high thermal efficiency. Its design allows the flue gas and air to flow in reverse, thereby obtaining a better heat transfer effect.

Disadvantages: This type of air preheater is now less used because it consumes more steel and its structure is not compact enough. In addition, it is prone to dust accumulation and is difficult to clean.

Tube air preheater

Advantages: The heat transfer components of the tube air preheater are mainly thin-walled steel pipes, which have good sealing, high heat transfer efficiency, and are easy to manufacture and maintain. These characteristics make it widely used in power station boilers and industrial boilers.

Disadvantages: The tubular air preheater is large in size, the steel pipe is easily blocked by ash and not easy to clean, and the flue gas inlet is also prone to wear. At the same time, it also faces the problems of low-temperature corrosion and ash accumulation.

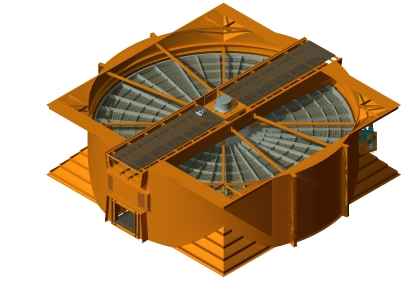

Rotary air preheater

Advantages: The rotary air preheater is a regenerative air preheater. The rotor drives the air preheater to rotate, so that the flue gas and air flow alternately in reverse. It has a high heat transfer coefficient and is widely used in large boiler generator sets.

Disadvantages: Although the rotary air preheater has high heat transfer efficiency, its structure is complex, and installation and manufacturing are relatively cumbersome. At the same time, air leakage problems are difficult to avoid, and the power consumption is large.

In actual applications, each air preheater has its applicable scenarios and advantages and disadvantages.

Choosing the right type of air preheater requires comprehensive consideration of factors such as the type, capacity, fuel characteristics, and expected maintenance workload of the boiler. For example, for large power station boilers, a rotary air preheater may be the most suitable choice, while for small and medium-sized industrial boilers, a tubular air preheater may be more cost-effective.