Customer Introduction

Shandong Pingyuan Hanneng Green Energy Co., Ltd. was founded in June 2011. Initially established as a Sino-foreign joint venture, the company was restructured on January 17, 2018, into a state-controlled mixed-ownership enterprise. The controlling shareholder is Shandong Shuitou Group Co., Ltd., a wholly-owned subsidiary of Shandong Shuifa Group, a first-tier state-owned enterprise under provincial management. The company’s registered capital is 116.7 million yuan.

The company is located in the eastern section of the Economic Development Zone in Pingyuan County, Dezhou City. It has invested in and developed the 30MW biomass cogeneration project, which is the first of its kind to be operational in Dezhou City. The project spans 281 acres with a total investment of 350 million RMB. It uses biomass fuels such as cotton stalks, fast-growing trees, fruit branches, and mulberry twigs. The project includes the installation of 2×75T/h sub-high temperature and sub-high pressure biomass water-cooled vibrating grate boilers, 2×C12MW steam turbines, 2×15MW generators, and various auxiliary production facilities. As the only renewable energy heat source enterprise in Pingyuan County, the company adheres to the philosophy of “The highest good is like water, the development is beneficial to people,” and is committed to providing clean, environmentally friendly, high-quality, and reliable energy products to society.

Project Background

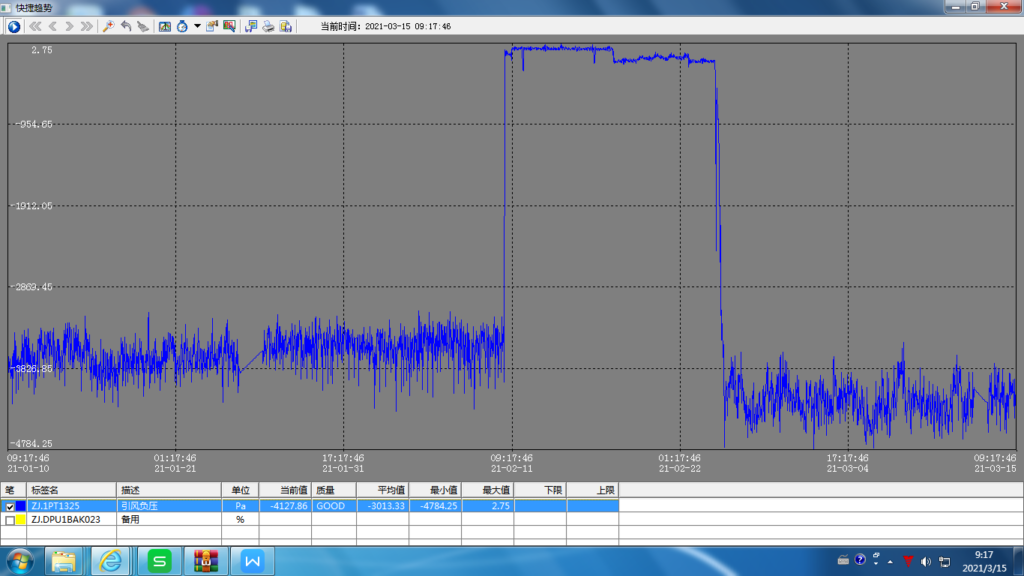

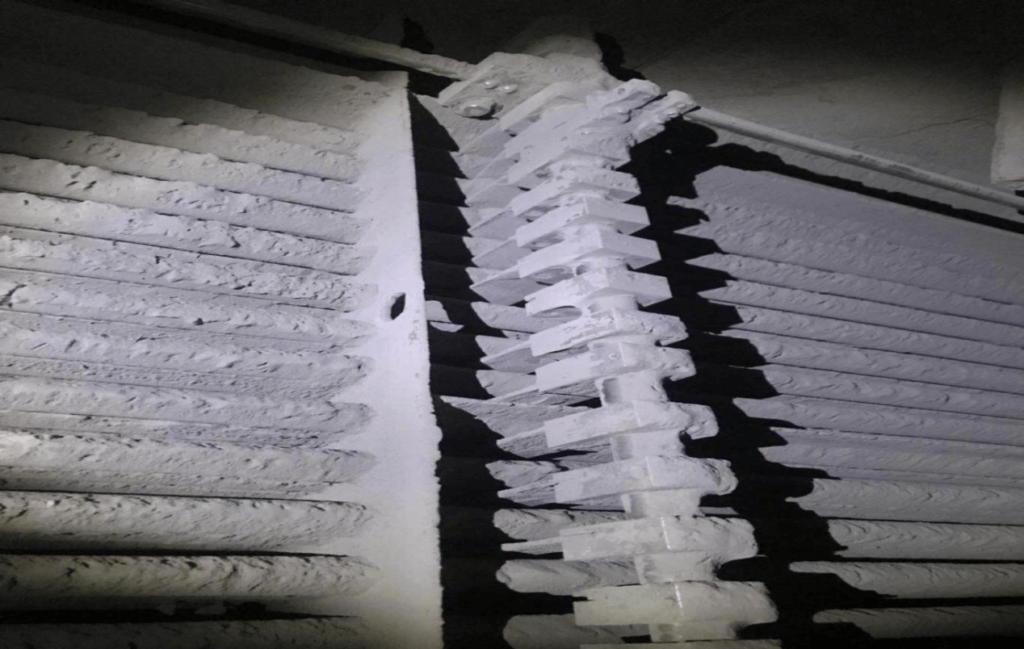

The boilers at this plant primarily utilize straw, bark, construction formwork, and old furniture as fuel. Agricultural waste and biomass fuels, which contain high levels of potassium and chlorine, tend to deposit as potassium chloride. Furthermore, potassium reacts with silicates in fly ash to create low-melting-point ash that is highly adhesive, leading to deposits on heat exchange components such as the air preheater. This ash buildup can cause blockages in the air preheater, resulting in insufficient negative pressure in the induced draft fan, which severely limits the boiler’s load-carrying capacity. The plant has faced numerous shutdowns due to these blockages, leading to substantial economic losses.

Solution

The shockwave soot blower initially installed during the boiler’s construction was insufficient to address ash blockage issues in the low-temperature section of the air preheater. Therefore, a more effective and reliable ash cleaning solution is needed.

In January 2021, the plant tested Bokk Tech’s intelligent automatic ash cleaning device on Boiler #1. This device integrates comb-shaped plates between the vertical rows of tubes in the air preheater. Driven by a chain, the plates move back and forth between the tube rows, removing ash deposits from the tube surfaces in real-time, thus preventing ash blockages.

With flue gas velocities of around 8-10 meters per second and a tube spacing of 25mm in the air preheater, the cleaning plates, measuring 80mm by 8mm, generate an accelerated vortex as they move between the tubes. This vortex helps dislodge ash from the tube walls, maintaining a certain level of cleanliness and preventing ash blockages between the tubes.

Equipment operation effect

After a three-month operational period, an inspection during the boiler shutdown confirmed that the vertical tubes in the air preheater were free of ash deposits. The boiler operated at a stable load, with a significant reduction in unplanned shutdowns, successfully meeting the goal of long-term continuous operation.

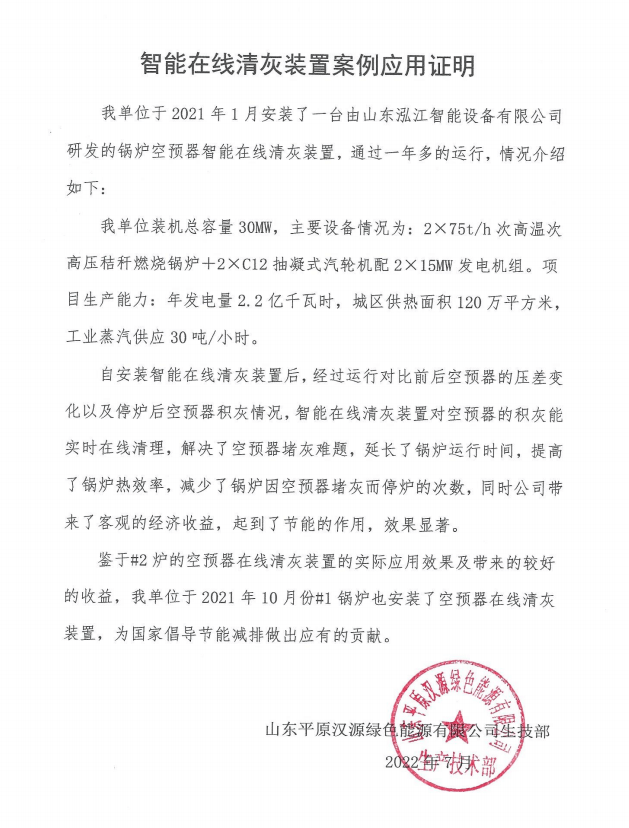

Customer feedback

About Us

Shandong Bokk Tech is dedicated to solve the problem such as ash blockage, corrosion and excessive exhaust gas temperature in the tubular air preheater of small and medium-sized boilers. We primarily manufacture automatic cleaning devices for tubular air preheaters and corrosion-resistant heat pipes. Our products are widely used in the thermal power plants, chemical plants, new energy sector, etc.

We offer customized services to customers around the world, allowing us to adjust product dimensions and other specifications based on your specific needs, to improve air preheater heat efficiency.

Share The Post